Application of Brake Tester in Vehicle Post-Maintenance Inspection

2025-06-25

The brake system is one of the most critical safety components in any vehicle. After a vehicle undergoes maintenance—particularly when it involves the braking system—it is vital to verify the system's performance before returning the vehicle to service. One of the most effective tools used for this verification is the brake tester. A brake tester plays a key role in post-maintenance inspection by ensuring that the braking system functions safely, efficiently, and in compliance with regulatory standards.

Importance of Brake Testing Post-Maintenance

Post-maintenance inspections are necessary to confirm that all repair work has been correctly executed and that the vehicle meets safety standards. Since brake system issues can lead to catastrophic outcomes, evaluating the effectiveness of braking components is essential. A brake tester allows mechanics and inspectors to quantify braking force, balance, and efficiency, thus reducing the risks of brake failure or uneven braking.

Function and Operation of a Brake Tester

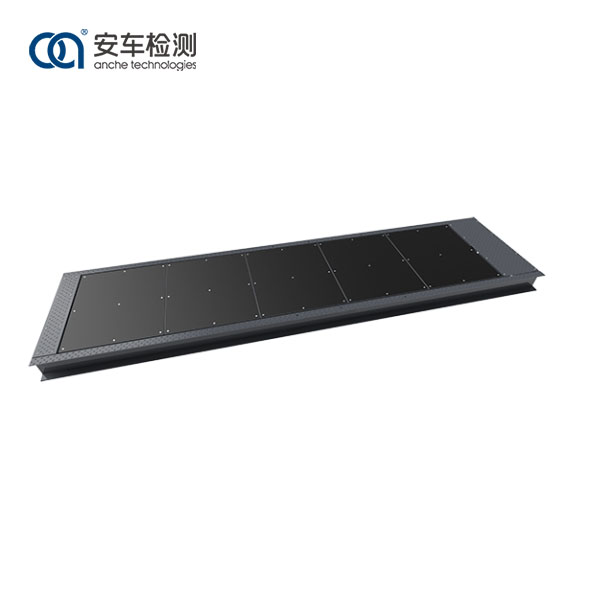

Brake testers typically come in the form of roller brake testers, plate brake testers, or decelerometers. The most common type, the roller brake tester, uses a set of motor-driven rollers to simulate road conditions and measure the braking force applied by each wheel. By comparing the braking forces on the left and right sides of the vehicle, the tester can identify imbalances, which may indicate improper repair or worn-out parts.

Advanced brake testers provide additional data such as brake force distribution, pedal force, axle weight, and braking efficiency percentage. These outputs offer comprehensive insights into the condition of brake pads, discs, drums, calipers, and hydraulic systems.

Ensuring Accuracy and Compliance

The use of brake testers ensures that the vehicle complies with national or international braking standards. In many regions, post-repair testing using calibrated brake testers is legally mandated. This not only ensures driver and passenger safety but also minimizes the risk of legal liability for garages and repair shops. Modern brake testers are often integrated with software systems that generate detailed test reports for documentation and future reference.

Advantages for Repair Facilities

For workshops and maintenance facilities, incorporating brake testers into the inspection process enhances service quality. It builds trust with customers by providing measurable proof of repair effectiveness. Additionally, it helps mechanics detect issues that may not be visible during a manual inspection, such as uneven pressure distribution or hidden hydraulic leaks.

Conclusion

The application of brake testers in vehicle post-maintenance inspection is essential for ensuring safety, reliability, and regulatory compliance. By providing objective, data-driven evaluations of a vehicle’s braking system, brake testers help technicians validate repair work, identify potential issues, and deliver vehicles back to the road with confidence. As automotive technology advances, brake testing equipment will continue to play a vital role in maintaining high safety standards in vehicle maintenance and repair.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.